Best practice welding of uncoated steel

Appearance of the welded area

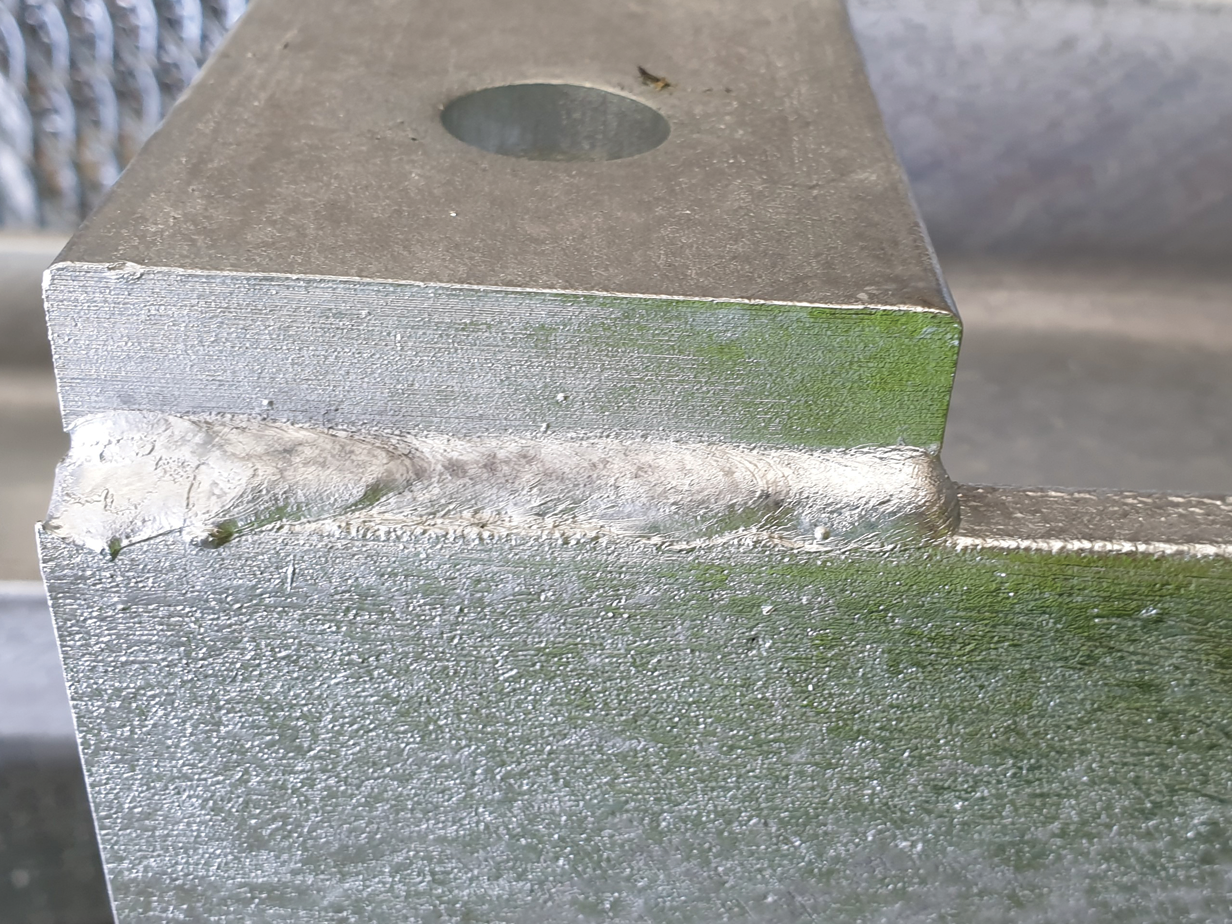

All professional welders strive to avoid weld defects. Some visual defects can cause significant problems in the galvanizing process or afterwards when the article is in use. The well-known welding defects such as slag inclusion, undercut, porosity, incomplete fusion, overlap, underfill, spatter, excessive convexity, excessive weld reinforcement, incomplete penetration, and excessive penetration are all known to lead to defects in the galvanized coating varying from the coating not forming properly in the area of the weld, an unattractive appearance, or even fracturing of the fabrication in the vicinity of the weld.

Weld defects that lead to undercuts, porosity, underfill and incomplete penetration all provide areas in the final fabrication where the galvanized coating may not fully form or moisture can collect after installation of the finished article. It is these areas that can lead to earlier corrosion of the steel and a reduction in the service life.

Chemistry of the welding rod

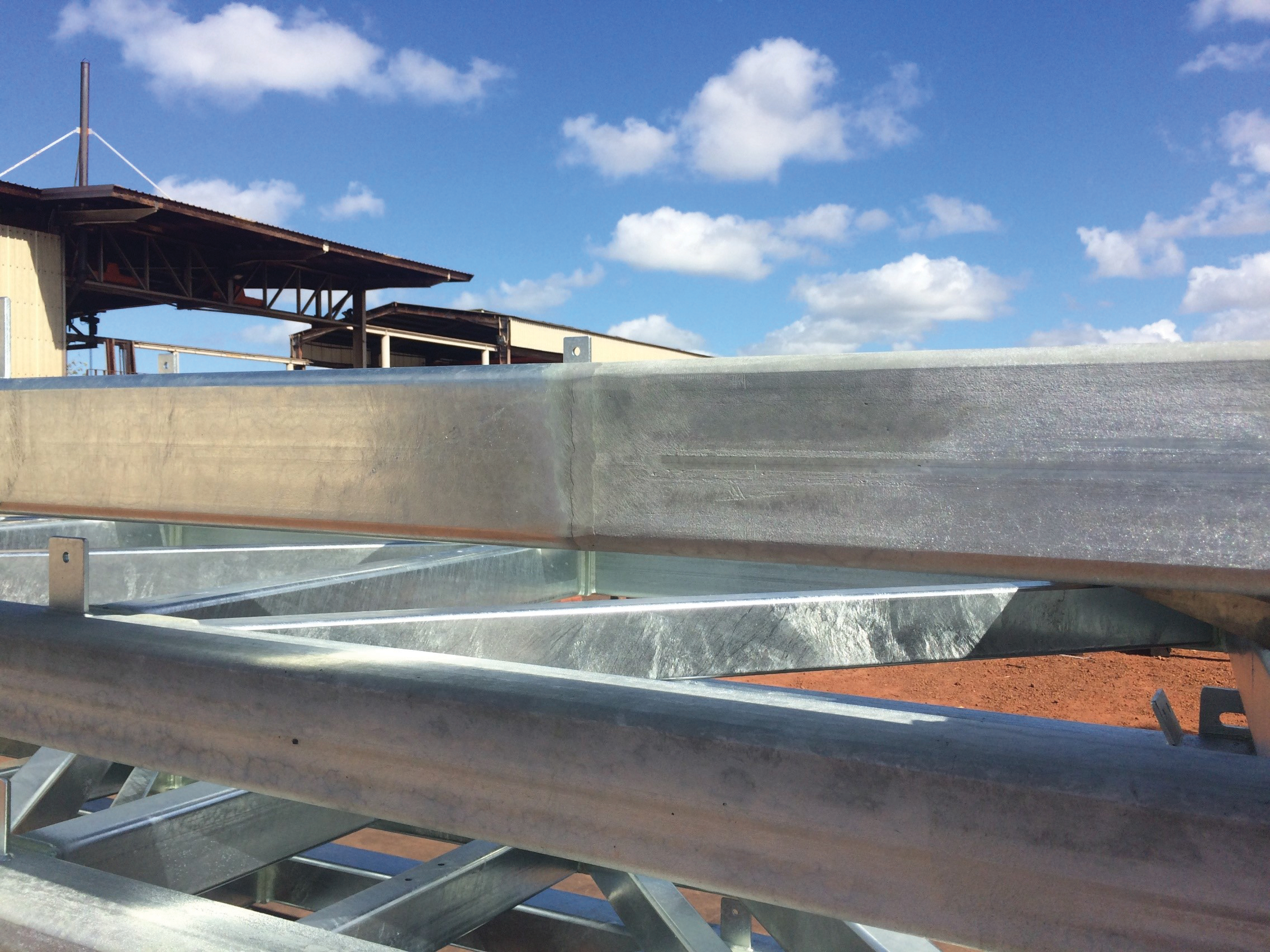

Due to the silicon content of some welding rods, welded areas may produce localised duller grey coatings or brighter shiny coatings when hot dip galvanized. The galvanized coating over the weld is normally sound and the appearance will have no detrimental effect on the corrosion protection. The development of dull or shiny coatings due to the silicon content of the weld metal cannot be controlled by the galvanizer.

In most case the configuration of the structure means the initial appearance of the weld after hot dip galvanizing is not critical to the overall appearance of the fabrication. However, on flat surfaces or when straight length tubular sections are joined by welding and the weld areas are ground flush prior to galvanizing, heavier grey coatings may still result due to the difference in the weld and base metal composition. Low silicon welding rods can be used to reduce this effect.

Managing weld splatter

The base steel surface cleanliness affects the quality of galvanized surface finish. Weld splatter (and flame cutting splatter) must be removed by the fabricator prior to galvanizing to ensure a quality surface finish is achieved. AS/NZS 5131 requires weld spatter to be removed for CC2, CC3 and CC4 construction categories. Removal is normally achieved by wire brushing, chipping or grinding.

Anti-spatter sprays and compounds should be avoided for steel that is to be hot dip galvanized (or painted) unless you have prior knowledge they can be removed in the normal pre-treatment process, as they can result in bare spots near to otherwise well-formed welds.

Removing welding slag

Arc welding slags are chemically inert in acid cleaning solutions and must be mechanically removed by the fabricator before articles are delivered to the galvanizer. Chipping, wire brushing, grinding or abrasive blast cleaning are suitable methods for cleaning in and around the welded area. Pay attention to cleaning the area around the join of the parent and weld metal.

Welding electrode manufacturers supply general purpose electrodes coated with fluxes which produce virtually self-detaching slags and their use is recommended.

Good joint design, combined with adequate access, makes it easier to produce sound continuous welds, avoid locked-in slag, and easy slag removal.

Due to the silicon content of some welding rods, welded areas may produce localised duller grey coatings or brighter shiny coatings when hot dip galvanized.

Welding overlapped surfaces

When fabricating assemblies with overlapped surfaces, it is best practice to use fully sealed welds when the gap between the surfaces is below 2.5 mm. This is due to zinc’s viscosity and its inability to penetrate such gaps. If unsealed after galvanizing, this will lead to ungalvanized surfaces which will corrode and can result in rust bleeding onto the surrounding galvanized surface. A fully sealed area will also require ventilation of the overlapped areas larger than 100 mm x 100 mm to avoid explosions. More information on best practice venting is included in the GAA’s Design Guide.

Welding to minimise distortion in the galvanizing process

The hot dip galvanizing process will not generally cause distortion if design and fabrication principles are correct. When steel fabrications do distort during hot dip galvanizing, the reasons have usually been ‘built-in’ at an earlier stage. Distortion almost always arises from the relief of stresses as the steel is dipped into the molten 450 °C Zinc of the hot dip galvanizing bath. Although such stresses may be inherent in the steel and may vary from batch to batch, they are more commonly caused during fabrication. Distortion may also occur if steels of significantly different thicknesses are joined together in a fabrication. Only very rarely is it caused by handling in the hot dip galvanizing plant.

Welding two pieces of steel together can result in extreme differences in temperatures within small areas of an assembly and hence significant residual stresses.

In addition to following the requirements of AS/NZS 1554, it is recommended that:

- Components of an assembly be pre-formed accurately so that they need not be forced, sprung or restrained during welding.

- Thick sections should be continuously welded.

- Thin sections and sheet fabrications may benefit from intermittent welding, depending on whether or not heat is conducted rapidly away from the weld, although more stress may arise at the starting point of the weld.

- Welded assemblies should be aligned so that the stresses are balanced rather than all pulling in the same direction.

Fabrication stresses can sometimes be eliminated by stress relieving before galvanizing. Early consultation between galvanizer, fabricator and designer is the key to success in avoiding distortion, through the incorporation of good design features.

Appendix A of AS/NZS 2312.2 is recommended as a further reference for specific information regarding good design practice for articles to be hot dip galvanized.

It is sometimes possible to straighten fabrications after hot dip galvanizing if distortion occurs, so long as the distortion has not affected the structural integrity of the fabrication.

The hot dip galvanizing process will not generally cause distortion if design and fabrication principles are correct.