Properties of sound welds in galvanized steel

General properties

When welding conditions are chosen to give sound welds in galvanized steel, the tensile, bend and Charpy impact properties are equivalent to those of welds in uncoated steel. Tests showed that the presence of zinc at the levels occurring in the weld metal does not affect tensile, bend or impact properties.

Fracture toughness

Crack opening displacement (COD) measurements and drop weight tests established that fracture toughness properties of welds are unaffected by the presence of galvanized coatings.

Fatigue strength

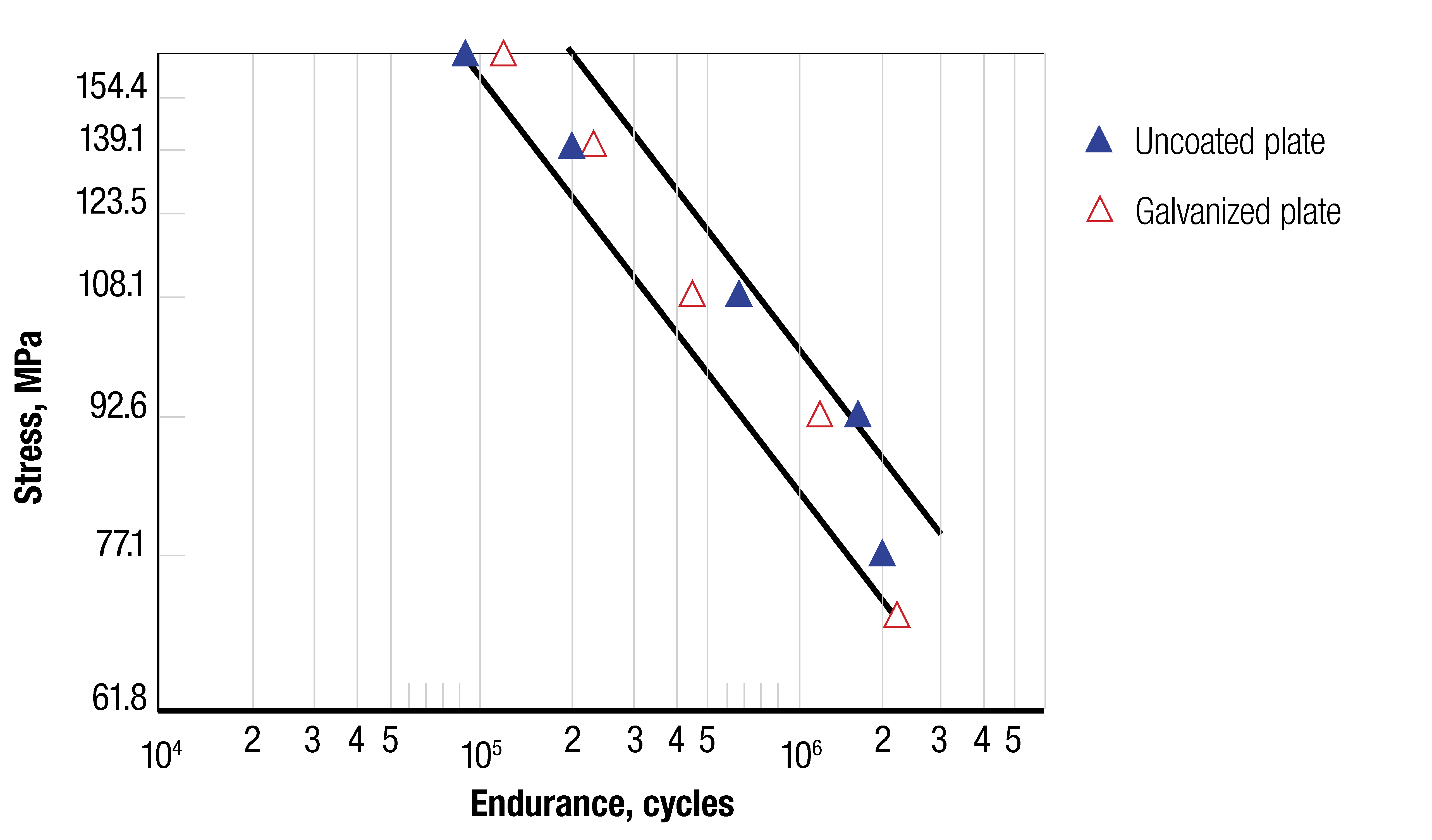

The fatigue strength of arc welds in galvanized steel is equivalent to welds in uncoated steel (Figure 14). Fatigue tests were carried out on fillet welded cruciform joints made by CO2 GMA welding with low silicon filler metal of the AWS Classification AWS A5.18:ER70S-2.

CO2 short circuiting GMA welds on 13 mm uncoated and galvanized Lloyds Grade A steel, AWS A5.18:ER70S-2 filler metal. (ref: EN Gregory, ‘The mechanical properties of welds in zinc coated steel’.)