Structural fasteners and bolting techniques

Connections are made up of components (cleats, gussets, brackets, and plates) and connectors (bolts, pins, and welds).

This guide only deals with bolted connections. It is critical in the design of structural connections that the structure can resist the design actions and that each element has a design capacity at least equal to the design action effects.

Strength designations (property class)

The strength of structural bolts is specified in terms of the tensile strength of the threaded fastener and defined according to the ISO strength grade system which consists of two numbers separated by a point, for example 4.6. The first number of the designation represents one hundredth of the nominal tensile strength (MPa) and the number following the point represents the ratio between nominal yield stress and nominal tensile strength.

For example, a property class 4.6 bolt

- Nominal tensile strength = 4 x 100 = 400 MPa

- Nominal yield strength = 0.6 x 400 = 240 MPa

Commercial fasteners

Commercial low carbon steel bolts used in the steel industry are manufactured to AS 1111.1 which calls for a minimum tensile strength of 400 MPa, with the property class designation 4.6. Design stresses are specified in AS 4100.

M12 hot dip galvanized commercial bolts are commonly used for connections in purlin and girt applications. Cleats and lightly loaded brackets typically use M16 bolts, while M20 and M24 bolts are normally used in general structural connection and as holding down bolts. The larger sized M30 and M36 bolts are often used as anchor bolts.

Table 2: Mechanical properties of property class 4.6 bolts

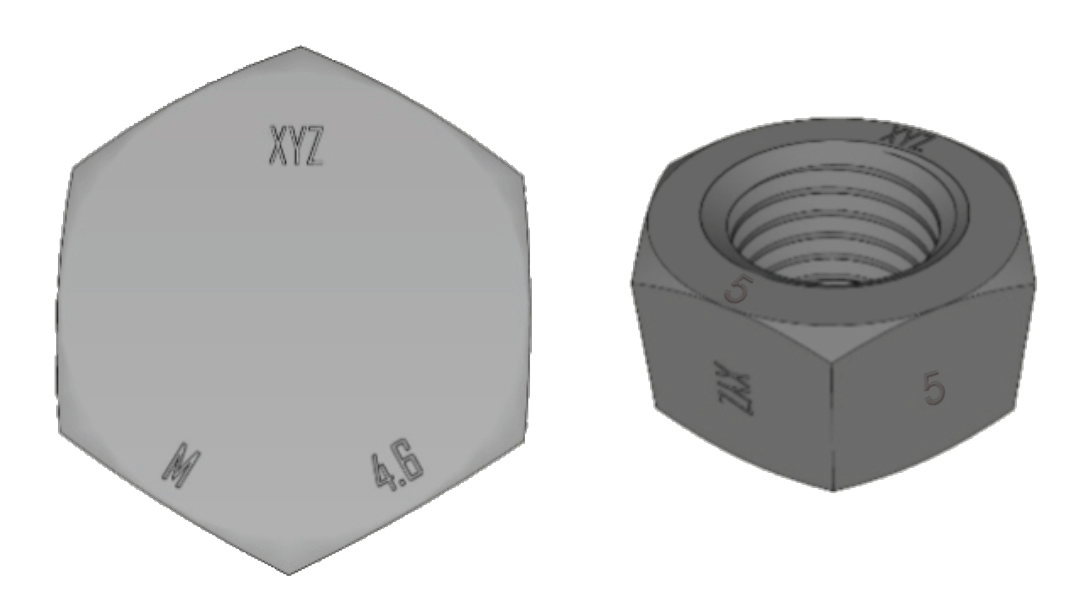

Identification

Commercial bolts usually carry the maker’s name and the metric M on the bolt head and may also carry the property class.

Nuts should be marked to identify the manufacturer as well as have a property class mark. Marking should be located on either the sides of the nut, or on the non-bearing face of the nut. Regular nuts and high nuts are mated with externally threaded fasteners according to their property class.

Nuts of a higher property class can replace nuts of a lower property class and it is common in Australia to use property class 5 nuts in conjunction with property class 4.6 bolts.

Hot dip galvanized flat washers have no marking requirements.

Tower fasteners (AS 1559)

Transmission towers are designed as critically stressed structures and the very large number of tower bolts used has provided the incentive to reduce weight and cost by application of the plastic theory basis for design. This design concept calls for a higher strength bolt than the standard commercial 4.6 bolt. The medium strength tower bolt to property class 5.6 was developed to meet this need and hot dip galvanizing is the standard finish used to provide corrosion protection matched to the structure.

As maximum shear strength values are required, the thread is kept out of the shear plane. Transmission towers are often erected in high snow country and it is also necessary to have a bolt with good low temperature notch toughness. Short thread lengths and specified notch ductility meet these requirements. Tower bolts are commonly used in the range of M12-M30.

Nuts are property class 5, double-chamfered and tapped oversize after galvanizing to tolerance class 6AZ. All nuts are provided with a clean, and dry to the touch, lubricant coating to prevent internal thread corrosion and seizure on assembly.

Table 3: Mechanical properties of tower bolts

There are two options for washers with tower bolts: a typical flat washer and a helical spring washer. Flat washers are slightly smaller than those used in

AS/NZS 1252.1 and without nibs. Spring washer designs were included in the 2018 edition of the Standard, using some of the requirements of AS 1968 (withdrawn) and are to be heat treated after coiling to a hardness of 450-540HV. AS 1559 has specific test methods for washers which differ from those in AS/NZS 1252.1

Nut locking of tower bolts

Transmission towers are constructed from galvanized structural sections using single bolted joints and positive prevention of nut loosening is necessary in critical situations. This requirement is met by effective initial tightening and some additional measures to ensure nut locking, such as punching and distortion of the bolt thread at the outer nut face after tightening or the use of galvanized prevailing torque type lock nuts.

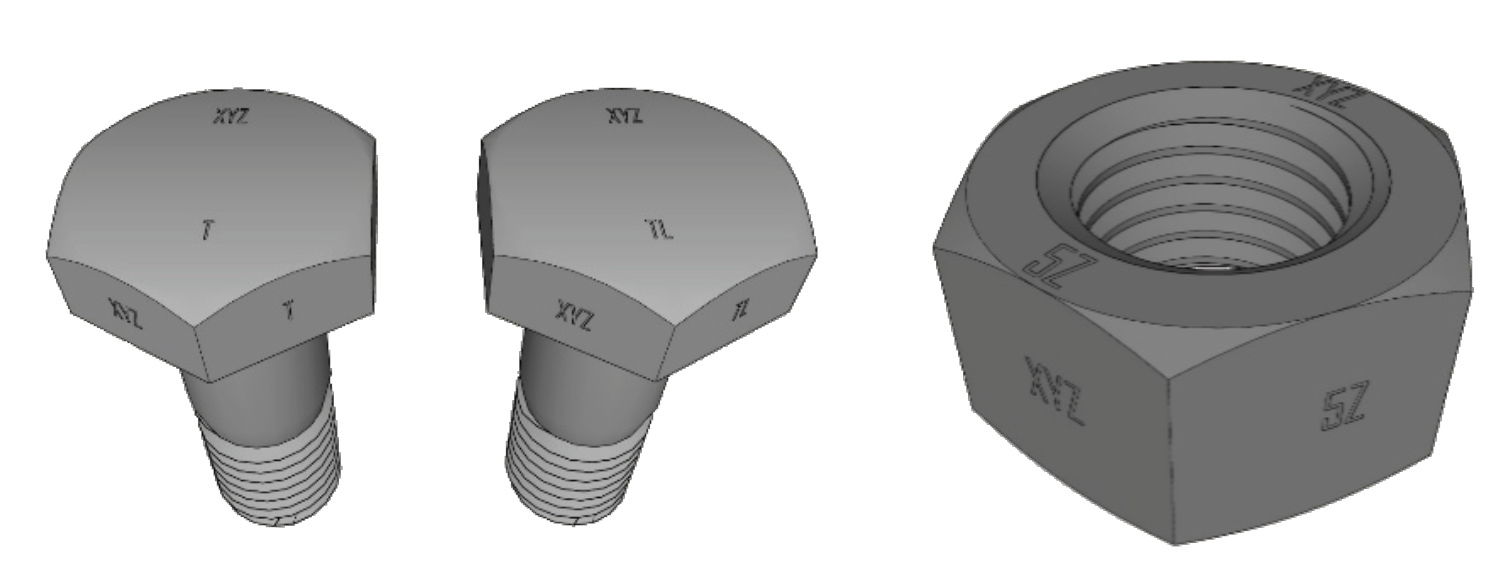

Identification of tower bolts

Galvanized metric tower bolts are indented with the letter T for Tower or TL for low temperature tower application. The indentation is located on either the top of the head or on one of the hexagon flats. The makers name should also be indented on the head of the bolt. Bolts may have markings showing the nominal bolt length in millimetres.

Nuts should be marked to identify manufacturer as well as including the property class mark alongside the letter Z. This indicates the tolerance class of the thread. Marking should be located on either the sides of the nut or on the non-bearing face of the nut.

Hot dip galvanized flat washers have no marking requirements. To avoid a reduction in serviceability, hot dip galvanized helical spring washers are also unmarked.

High strength fasteners

These fasteners are commonly used in structural applications. M16 hot dip galvanized high strength structural bolts are commonly used for structural connections in small members, while M20 and M24 are commonly used in both flexible and rigid connections. M30 diameter is used less in structural applications, particularly when full tightening is required to AS 4100, because of the difficulty of on-site tensioning to achieve specified minimum bolt tensions. M36 should never be specified if full tensioning to AS 4100 is required.

Property class 8.8

The bolt and nut material properties between AS/NZS 1252.1 and EN 14399-3 System HR are identical as both rely on ISO 898-1 (AS 4291.1 (12)) and ISO 898-2 (AS/NZS 4291.2 (13)), respectively.

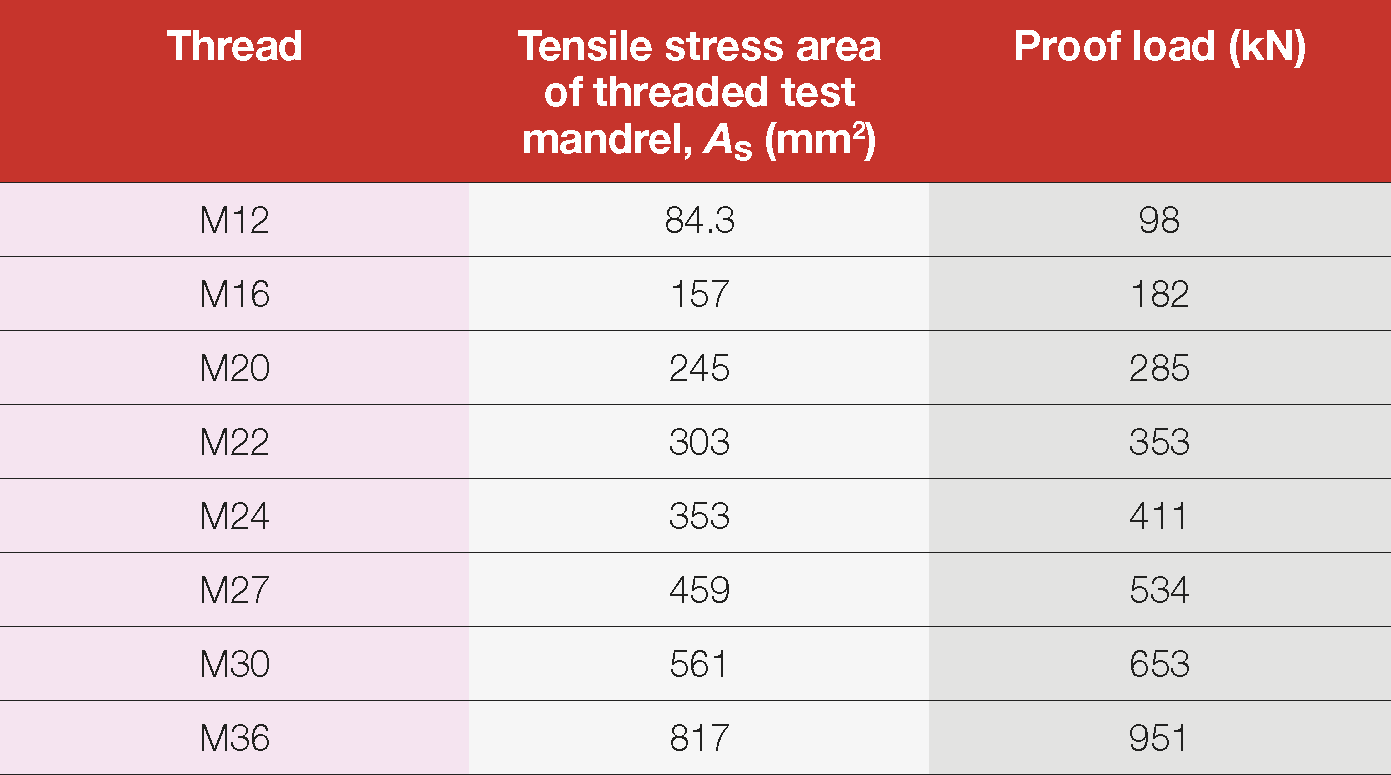

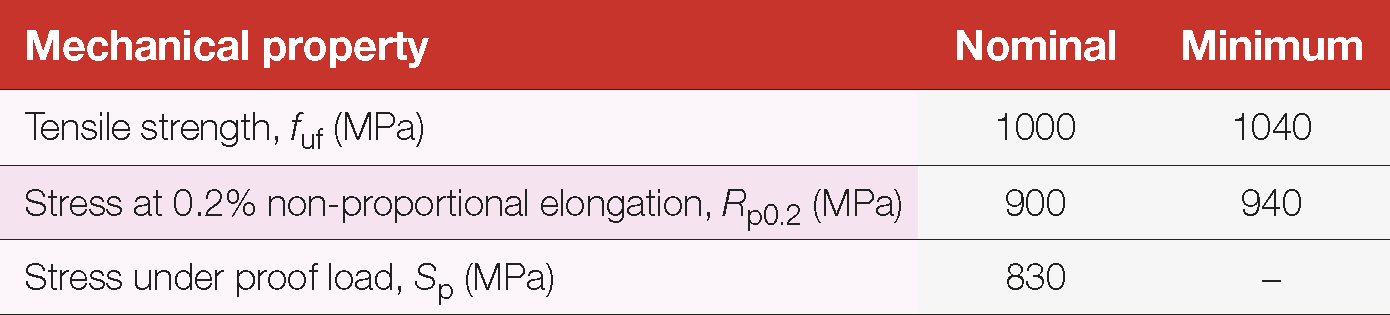

Table 4: Mechanical properties of property class 8.8 high strength bolt assemblies to As/Nzs 1252.1

Hot dip galvanizing affects bolt-nut assembly strength primarily because the nut must be tapped oversize to accommodate the thickness of the zinc coating on the bolt thread. The oversize tapped thread reduces the stripping strength of the nut when tested on a standard size threaded mandrel.

The proof load requirements for hot dip galvanized nuts under the requirements of AS/NZS 1252.1 differ significantly from that shown in AS/NZS 4291.2. There are minor differences in the material hardness requirements for washers with AS/NZS 1252.1 specifying a hardness of 320-390 HV (33-41 HRC), irrespective of whether the washers have plain finish or are hot dip galvanized, while EN 14399-5 calls up hardened and tempered washers to ISO 4759-3 with a hardness range of 300 HV to 370 HV.

In high strength bolting, correct tightening is essential and AS/NZS 1252.1 specifies that all high strength nuts must meet the full stripping load when tested on a standard-size hardened mandrel. To meet this requirement, galvanized high strength nuts have a higher specified hardness than uncoated nuts in accordance with Table 3.1 of AS/NZS 1252.1.

Table 5: Mechanical properties of hot dip galvanized high-strength steel nuts

Table 6: Proof loads for hot dip galvanized high strength steel nuts from AS/NZS 1252.1

Identification

Galvanized high strength bolts to AS/NZS 1252.1 property class 8.8 can be identified by three radial lines on the bolt head, with the maker’s name and the property class symbol which can be located on either a side face or the top of the head.

Nuts to property class 8 for use with structural bolts can be identified by three circumferential lines on the face of the nut, the property class symbol, which is indented on an external face, and the manufacturer identification trademark on a similar face. Relative to nominal thread size, high strength structural bolt heads and nuts are visibly larger than commercial bolts and nuts.

Flat round washers for use with high strength structural bolts can be identified by three circumferential nibs.

The alternative 8.8 HR bolts do not have the radial lines, but instead have the property class and HR marked on the head of the bolt.

Nuts are marked similarly to the bolt, while washers are plain round without the nibs, but are marked with the maker’s name and H symbol.

Property Class 10.9

High strength structural bolt assemblies for preloading that are manufactured in accordance with EN 14399-3, System HR, property class 10.9 are the only additional assembly type that is deemed to satisfy the requirements of AS/NZS 1252.1 and as such may be used where reference is made to property class 10.9 fasteners conforming to the Standard.

Currently there is limited use of higher grade 10.9 bolt assemblies in the Australian market, although the potential increase in structural capacity of connections from the use of property class 10.9 bolts instead of 8.8 bolts may see this increase over time.

High strength bolts assemblies to property class 10.9 come in sizes M12, M16, M20, M24, M30 and M36, although the most used sizes are M20 and M24.

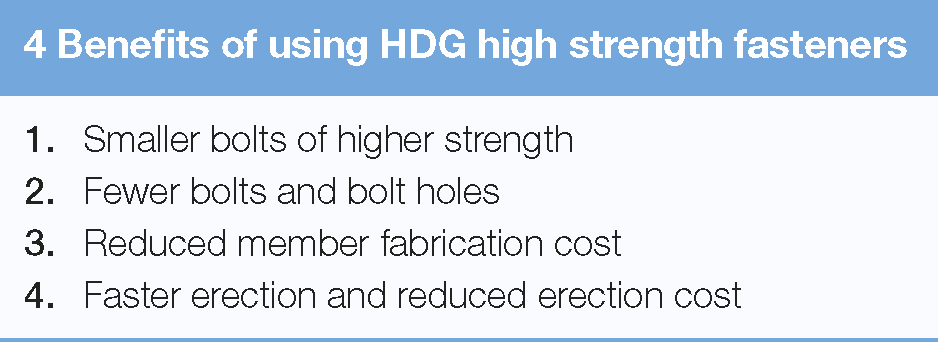

Table 7: Mechanical properties of high strength bolt assemblies to EN 14399 system HR property class 10.9

Identification

Hot dip galvanized high strength bolts to AS/NZS 1252.1 property class 10.9 can be identified by the maker’s name and the property class (10.9HR) which is to be located on either a side face or the top of the head.

Nuts to property class 10.9 for use with structural bolts can be identified by the property class and the maker’s name or trademark on a similar face.

Relative to nominal thread size, high strength structural bolt heads and nuts are visibly larger than commercial bolts and nuts.

Flat round washers for use with high strength structural bolts of property class 10.9 can be identified by the property class and the maker’s name or trademark on a similar face and are dimensionally larger than commercial and high strength washers.

The strength of structural bolts is specified in terms of the tensile strength of the threaded fastener and defined according to the ISO strength grade system.

There are two options for washers with tower bolts: a typical flat washer and a helical spring washer.

Hot dip galvanizing affects bolt-nut assembly strength primarily because the nut must be tapped oversize to accommodate the thickness of the zinc coating on the bolt thread.