Transport and storage

New galvanized products should be handled, transported and stored with the normal care given to any other surface-finished building material.

New galvanized steel surfaces which have not yet developed the patina of protective zinc carbonates, which normally contributes to the long life of aged coatings, are highly reactive and susceptible to premature corrosion under poor conditions of exposure.

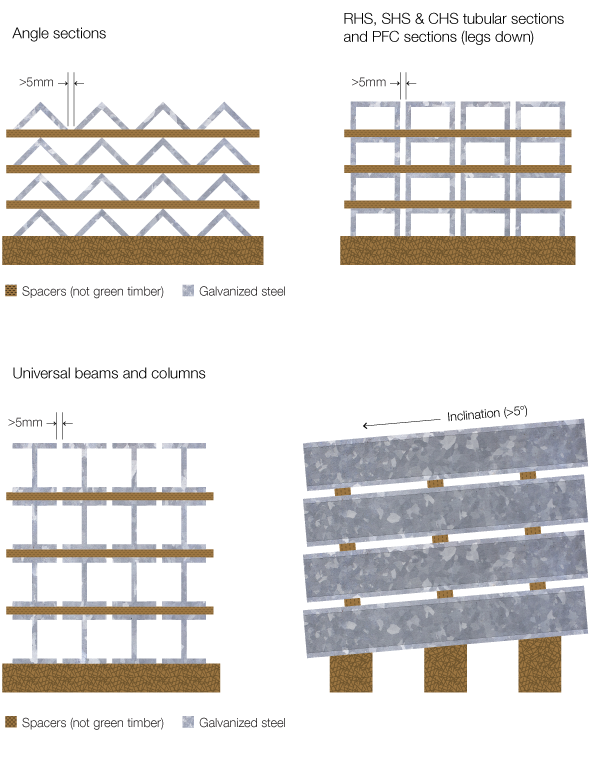

Transport should be under dry, well ventilated conditions. When stored on site, material should be covered where possible and raised clear of the ground on dunnage or spacers. When shelter is not possible material should be stacked to allow drainage of rainwater. Storage in contact with unseasoned timber, mud or clay will lead to surface staining and in severe cases, premature corrosion.

Clearance for ventilation between stacked galvanized products is necessary under damp or humid conditions to avoid the possibility of wet storage stain and the development of bulky white corrosion product. Attack on the galvanized coating producing white corrosion is caused by the retention of condensation or run-off water between the contacting surfaces under conditions of restricted air circulation. The attack is frequently superficial despite the relative bulkiness of the corrosion product but may be objectionable because of appearance. In severe cases corrosion product should be removed to allow the natural formation of a protective zinc carbonate film. See Advisory Note AN 05, Wet Storage Stain, for more information.

It is common in Australia and New Zealand for the galvanizer to apply a simple passivation treatment as part of the quenching process which will minimise wet storage stain. Under severe conditions passivation should not be relied on and new galvanized products should be packed carefully and protected for shipment and storage.

Hot dip galvanized coatings can withstand chains used during transport, although straps are preferred for thicker coatings which are usually more susceptible to damage.