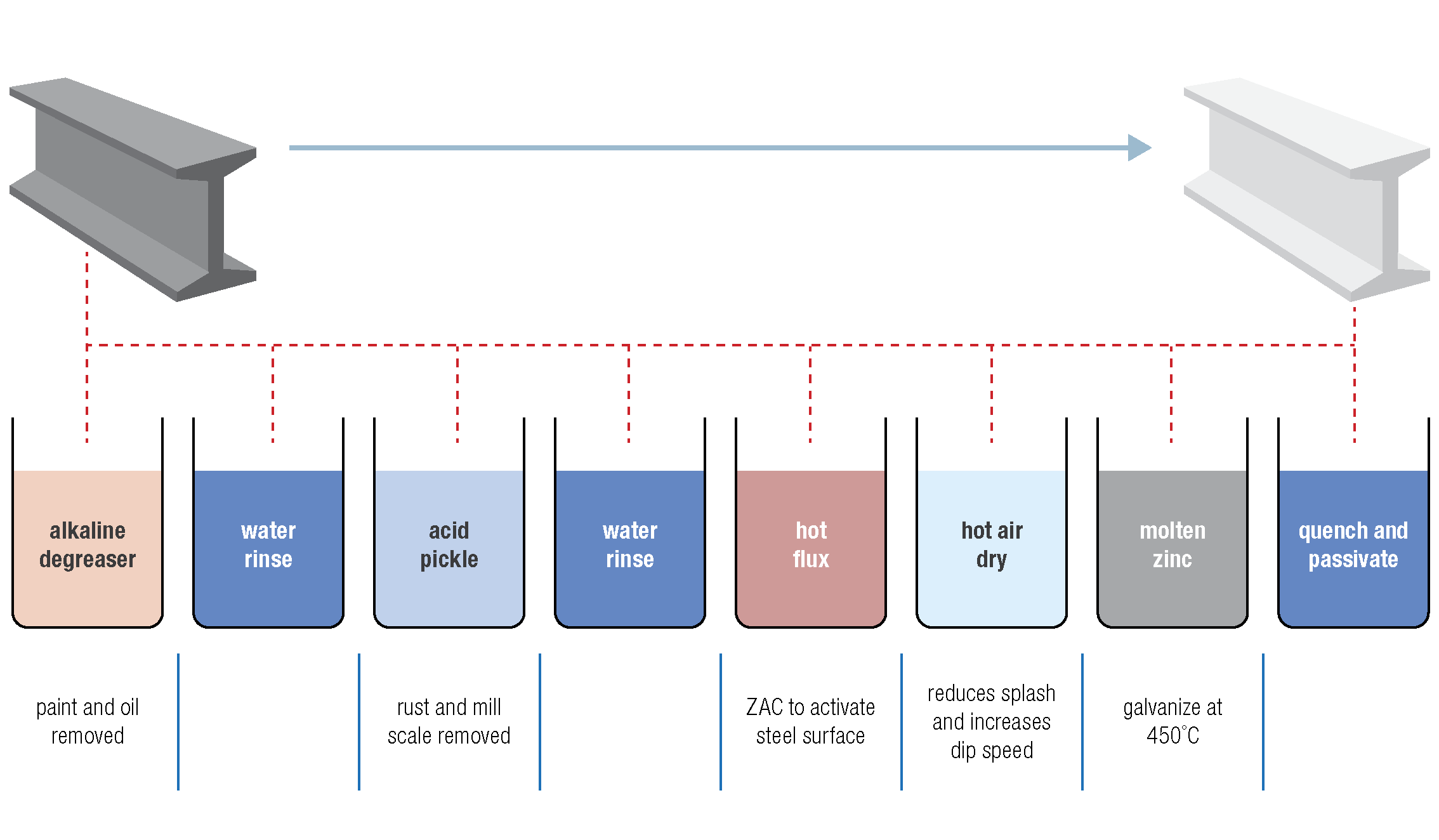

The galvanizing process

In Australia and New Zealand, hot dip galvanized coatings are generally applied to structural steel sections, beams and columns, fabricated steel assemblies, castings, steel reinforcement and miscellaneous steel components using AS/NZS 4680, Hot dip galvanized (zinc) coatings on fabricated ferrous articles, while threaded fasteners are hot dip galvanized using AS/NZS 1214, Fasteners — Hot dip galvanized coatings. Continuous, semi-continuous or specialised plants are used to apply the hot dip galvanized coating to semi-finished products such as wire, tube or sheet and coil and these processes and Standards are not covered here.

Pre-treatment

Pre-treatment of the steel is required to provide a chemically clean steel surface that can be presented to the molten zinc in the galvanizing bath, so that the metallurgical alloying reaction and bonding of the zinc coating to the steel can occur. For this to be achieved it is necessary to remove any organic surface contamination, such as oil and paint, so that the pickling process, using mineral acids, can be effective in removing surface oxidation or mill scale.

Abrasive blast cleaning

Abrasive blast cleaning is not normally used to prepare steel fabrications prior to galvanizing although there are times when it will be recommended for coating quality purposes.

Blast cleaning with iron or steel shot or grit may be used to remove lacquers or varnishes, sand and other surface contamination that cannot be removed by the standard chemical methods. It is not always possible to blast internal surfaces and weld areas and these areas especially should be visually inspected before galvanizing.

Abrasive blast cleaning is also used to prepare malleable and grey iron castings for galvanizing as adherent moulding sand is not readily removed by pickling.

Blasting with steel grit can be used to increase the surface profile of the steel in cases when a thicker zinc coating than the standard is specified in the contract, to increase the service life of the product. Abrasive blasting of steel to achieve thicker coatings is covered in GAA Advisory Note AN 02.4.

Degreasing and paint removal

In Australia and New Zealand, the first step in preparing the steel surface is for the steel to be dipped into an alkali degreasing solution, generically known as ‘caustic’. Hot caustic solutions are usually operated at about 10% sodium hydroxide (NaOH), at 70°C – 90°C and ambient temperature caustic solutions are also in common use.

Immersion times in this solution can vary, depending on the nature and degree of the contamination, and although immersion time can be less than 5 minutes, it can sometimes take longer than 24 hours to remove heavy grease or oil, paints, lacquers, and varnishes, particularly finishes encountered on some larger diameter pipe products. Often it becomes more economical to pre-remove such adherent contamination by mechanical cleaning and it is usual for the galvanizer to recommend that abrasive blast cleaning be employed for this purpose.

Alkali degreasing is usually followed by a rinsing step, to minimize carryover of the caustic solution to subsequent treatment processes.

Pickling

During the acid pickling process, contaminants such as rust and scale are removed without attacking the underlying steel. Hydrochloric acid (HCl) is the most commonly used acid, although sulfuric acid (H2SO4) is also used. H2SO4 pickling is slower, more likely to lead to pickling defects and forms sludge more readily but is consumed slower than HCl. The concentration of HCl will vary in through its life, but typically within the range 6 – 14% and is normally operated at ambient temperature. Most galvanizing plants have multiple acid baths of varying strengths. HCl is also used to strip faulty galvanized coatings from defective articles.

Some plants, those with enclosed pickling systems or where they are located in cooler climates and during winter months, heat the acid to 25°C – 35°C, as these higher temperatures can increase the pickling rate and lower iron solubility.

The required pickling time and result will depend on the steel composition; the previous processing of the steel (e.g., heat treating); the condition of the steel (rust and mill scale will take longer to remove if thick); whether there are acid inhibitors or accelerators used; and the working conditions such as agitation of the parts. Pickling time can vary from as short as 10 – 20 minutes for articles which are otherwise ‘clean’ to several hours for heavily rusted articles.

Fluxing

The flux process is designed to activate the pickled and rinsed articles to ensure a fast and consistent reaction with the molten zinc occurs when the product enters the bath.

The most common method for fluxing is achieved by dipping into an aqueous solution of zinc ammonium chloride, called pre-fluxing. Pre-flux tanks normally operate at 50°C – 70°C and at concentrations of 200 – 300g/l flux strength. If possible additional drying of the pre-fluxed work in a drying pit or tunnel, prior to dipping can be advantageous to galvanized quality, zinc and zinc residue reduction and reduced fume emissions.

Dipping

On immersion in the galvanizing bath the steel surface is wetted by the molten zinc and reacts to form a series of zinc-iron alloy layers. To allow formation of the coating the work remains in the bath until its temperature reaches that of the molten zinc, in the range of 445°C – 465°C. The temperature range is usually tightly controlled by the galvanizer as excessive variation leads to rapid wear of the kettle which is expensive and time consuming to replace or repair.

The work is then withdrawn at a controlled rate and carries with it an outer layer of molten zinc, which solidifies to form the relatively pure outer zinc coating.

The period of immersion in the galvanizing bath varies from a few minutes for relatively light articles, to 10 minutes or longer for larger structural members.

Galvanizing fasteners and small components

Fasteners and small components are loaded into perforated cylindrical steel baskets. After degreasing, acid pickling, and pre-fluxing, baskets are lowered into the galvanizing bath. After withdrawal from the molten zinc, baskets are raised without delay and spun or centrifuged at high speeds for 15 to 20 seconds. Excess zinc is thrown off, providing a smooth, uniform coating, and maintaining the integrity of threaded items.

Threaded fasteners and washers are galvanized to AS/NZS 1214 (see Table 2) while all other spun or centrifuged articles are galvanized to AS/NZS 4680 (see Table 3).

Progressive Dipping (commonly known as “Double Dipping”)

Progressive dipping is a term used to describe the process of galvanizing an item which is longer, wider or deeper than the relevant available bath dimensions. In this procedure, the item is lowered into the bath so that half or more of its ‘over dimension’ is immersed in the molten zinc pool. When the galvanized coating has been achieved on the immersed section, the item is withdrawn from the bath and adjusted in handling so that the ungalvanized portion can be immersed in the bath. In this procedure an overlap of zinc coating will occur, and this will normally have to be addressed in the case of visually obvious structural elements. Progressive dipping increases the possibility of dimensional instability (distortion) of fabricated items. Guidance in these cases should be sought from the galvanizer at the design stage.

Quenching and Passivation

Upon extraction from the galvanizing bath the item is then usually quenched to cool which usually contains an inhibitor to provide passivation of the zinc surface to prevent early oxidation.

The resulting galvanized coating is tough and durable, usually comprising a softer, relatively pure zinc outer layer and a series of tough, hard zinc-iron alloy layers metallurgically bonded to the underlying steel, which completely cover the article and provide excellent resistance to abrasion.

An important advantage to the galvanizing process is that visual inspection shows that work is completely protected and gives an excellent guide to coating quality.

The coating thickness requirements of articles galvanized to AS/NZS 4680 are listed in Table 1.