Hollow vessels

- Hollow vessels may require temporary stays during the galvanizing process to prevent distortion

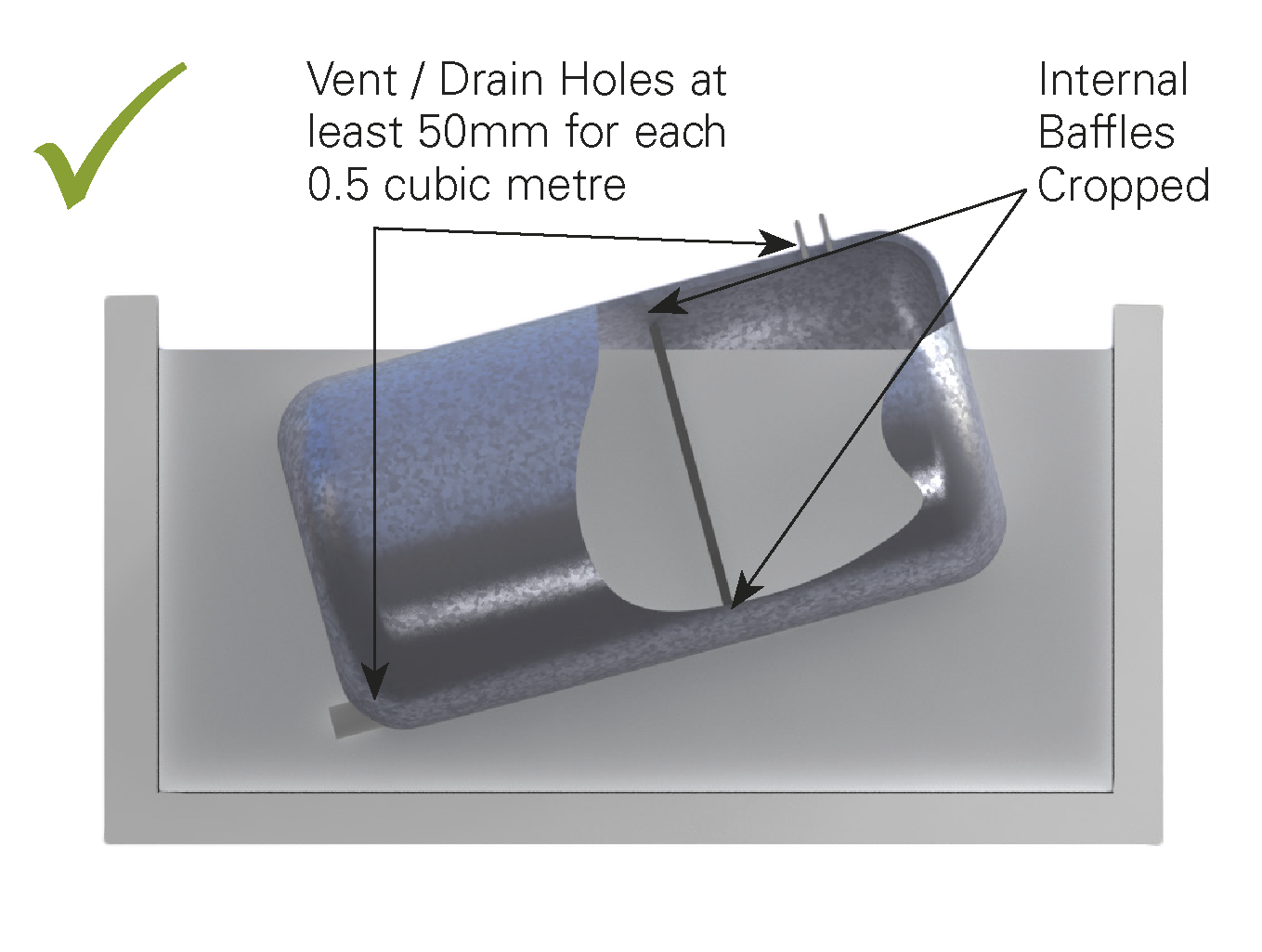

- Hollow vessels should have at least 1 vent hole and 1 drain hole

- Standard minimum venting and draining for an enclosed volume is a 50mm diameter hole for each 0.5m3 (see Table 4)

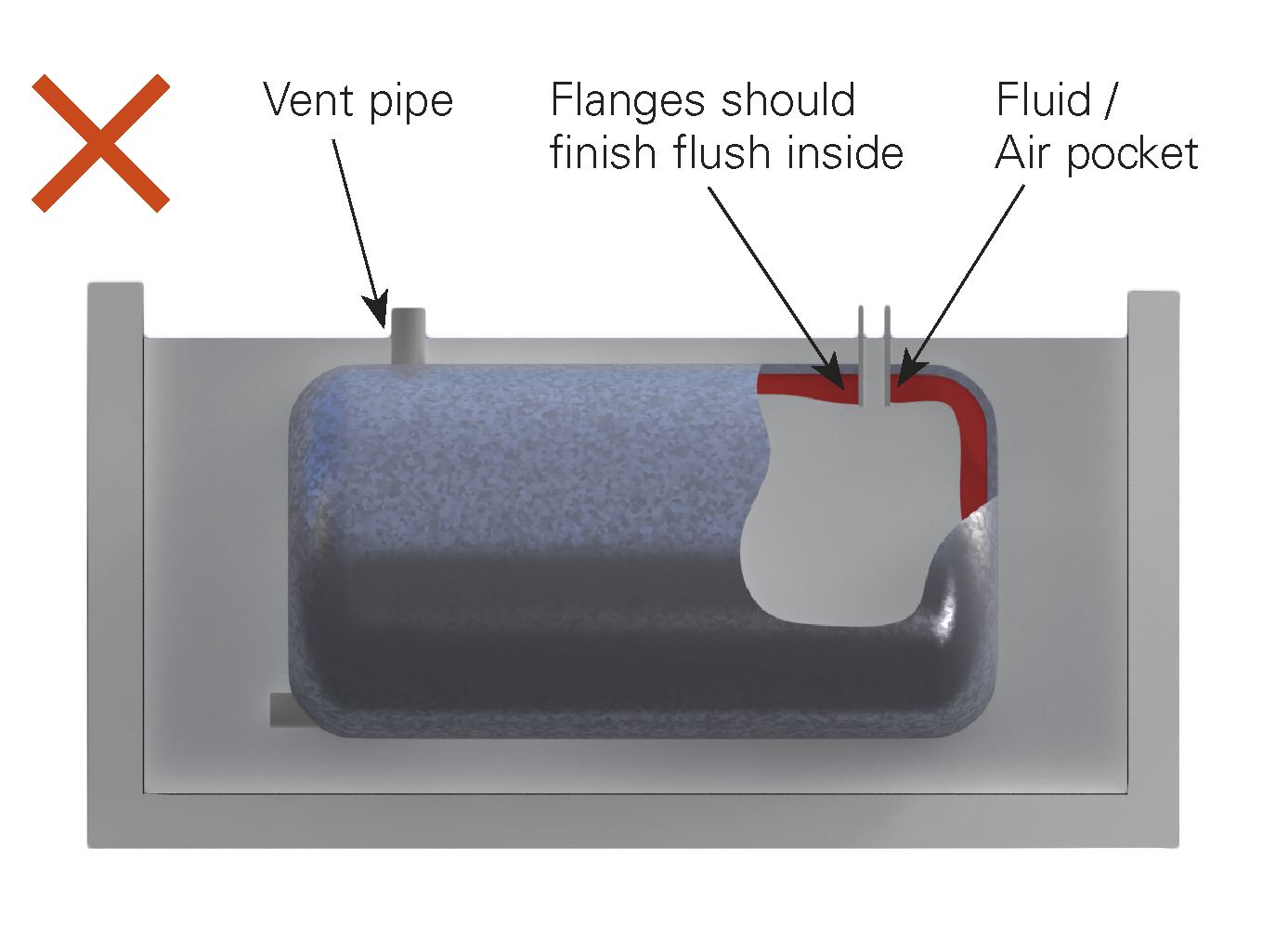

- Openings should finish flush inside the vessel

- Baffles inside vessels should have openings to allow free flow of liquid throughout. A minimum of 75mm snipes is required. See Figures 8 to 11 for more information on snipes.

Table 4: Minimum hole sizes for hollow vessels

Section Volume (litres) | 1 Hole | 2 Holes | 4 Holes |

500 | 50 | 35 | 25 |

1000 | 70 | 50 | 35 |

1500 | 90 | 65 | 45 |

2000 | 100 | 70 | 50 |

2500 | 115 | 80 | 55 |

3000 | 125 | 90 | 65 |

3500 | 135 | 95 | 70 |

4000 | 145 | 100 | 70 |

4500 | 150 | 110 | 75 |

5000 | 160 | 115 | 80 |

5500 | 165 | 120 | 85 |

6000 | 175 | 125 | 90 |

6500 | 180 | 130 | 90 |

7000 | 190 | 135 | 95 |

7500 | 195 | 140 | 100 |

8000 | 200 | 145 | 100 |

8500 | 210 | 145 | 105 |

9000 | 215 | 150 | 110 |

9500 | 220 | 155 | 110 |

10000 | 225 | 160 | 115 |

Figure 28 – Hollow Vessels – Good Design

Figure 29 – Hollow Vessels – Bad Design