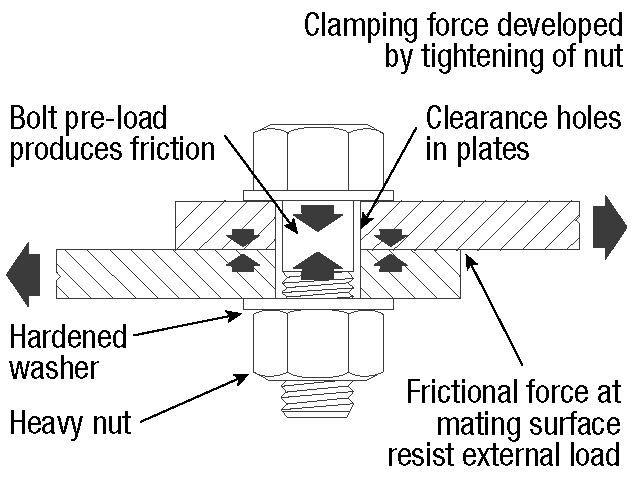

Modes of force transfer in bolted joints

In the design of individual bolts in bolted structural connections, there are three fundamental modes of force transfer:

- Bearing-type connection: A connection made using either snug-tight bolts, or high-strength bolts tightened to induce a specified minimum bolt tension, in which the design action is transferred by shear in the bolts and bearing on the connected parts at the strength limit state.

Friction-type connection: A connection made using high-strength bolts tightened to induce a specified minimum bolt tension so that the resultant clamping action transfers the design shear forces at the serviceability limit state acting in the plane of the common contact surfaces by the friction developed between the contact surfaces.

Axial tension mode: Forces to be transferred are parallel to the bolt axis – may apply in combination with other bolting categories.

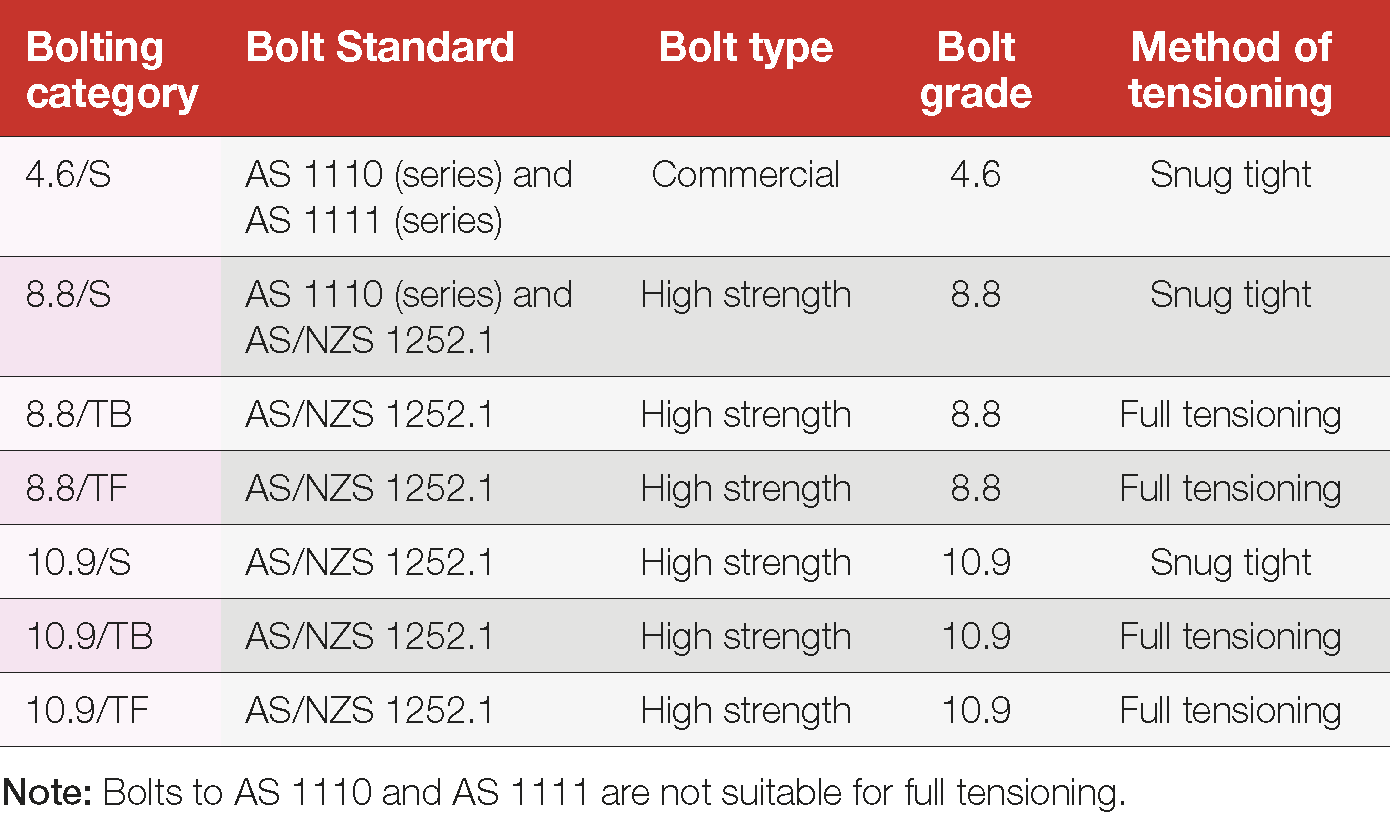

Bolting category system

The bolting category identification system is used to identify the property class and the bolting design procedure.

S represents snug tight, where snug tight is the tightness attained by a few impacts of an impact wrench or by the full effort of a person using a podger spanner to bring the plies into firm contact. It is the final mode of tightening for bolting categories including the designation S (e.g. 8.8/S), and the first step in full tensioning for bolting categories including the designation TF and TB (e.g. 10.9/TB).

Note: Firm contact occurs when the plies (the plates that form part of a bolted connection) are solidly seated against each other, although this does not have to be continuous contact.

High strength structural bolts in the snug tight condition can be used in flexible joints where their extra capacity can make them more economic than commercial bolts. The level of tightening achieved is adequate for joint designs where developed bolt tension is not significant. Behaviour of the bolt under applied loads is well known and accepted.

TB represents fully tensioned, bearing type joint

TF represents fully tensioned, friction type joint

AS 4100 specifies that friction type joints must be used where no slip is acceptable. They should also be used in applications where joints are subject to severe stress reversals or fluctuations as in dynamically loaded structures such as bridges, except in special circumstances as determined by the engineer. Where the choice is optional, bearing type joints are more economic than friction type.

Table 8: Bolts and bolting category

The bolting category identification system is used to identify the property class and the bolting design procedure.